I Found the Best Value T-Shirt Made in the USA

One man's journey to dramatically overcomplicate the purchase of 3 white t-shirts.

I'm about to make a bold claim. I think I've found the best value plain white t-shirt that's made in America. Not the most premium. Not the least expensive. The best value.

And in this post I'm going to tell you the story of the journey I went on to find it and what it took to buy it.

Backstory

I'm the type of guy who overcomplicates things. Three months ago, I decided to replace some of my old, ratty t-shirts from when I was in high school with new, crisp white tees.

Now, most people would probably just go out and buy a six-pack of t-shirts from Costco for $20.

But I'm obsessed with finding the best value for money. And no shade to anyone who's perfectly fine rocking the Kirkland classic, but cheap is not how I personally define value.

Which leads me to part one of my story:

Part I: What makes a good value t-shirt?

To me, value is a comparison between price and three other factors:

- What something is made of

- How it's made

- Who it's made by

For the past few months, I've been researching to see out how this framework applies to the humble white t-shirt. Here's what I've found:

1) What it's made of

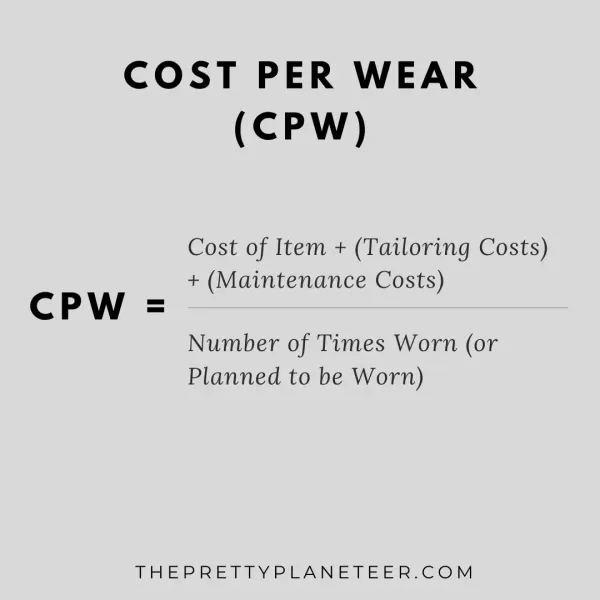

When it comes to creating a great t-shirt, the quality of the fabric is vital. Cheap t-shirts are usually made with cheap fabrics that pill, tear, shrink, and stretch very easily. This means although they boast a lower price tag, their price-per-wear is actually higher than garments made of thicker, better-knit, and generally higher-quality fabrics.

Cheap t-shirts are also often made with polyester or plastic in order to reduce costs. There is a lot of evidence that polyester clothing is really bad for the environment and growing evidence that it's also probably bad for our bodies.

So, to me, the best value t-shirt is made of an organic, natural, or even recycled fiber like cotton. It's spun and knitted in a way that gives the shirt a smooth feel while still being durable. And the fabric is thick enough to not make me feel exposed while wearing it.

2) How it's made

Next, let's talk about how a great t-shirt is made. There is so much to know about garment construction, and I've barely scratched the surface in my research. But in general, it seems like a well-made t-shirt is mostly about the collar. Ideally, it should be ribbed, double-stitched, and taped all the way around the back of the neckline. This ensures the collar stays flat and tight over the life of the shirt.

Everything else regarding stitching patterns, tubular vs. side seams, or the overall fit is mostly down to personal preference. The only other thing to really look out for in a t-shirt is that you want the garment to be pre-shrunk— that way there's very little variation between your first wear and your last.

3) Who it's made by

Finally, maybe the most important value factor for me is who it's made by. And I'm not talking about the brand here. That's who it's sold by. I mean the actual workers making the shirt.

There's an old saying that, "If you're not paying for it, someone else is," and factoring in the ethics and economic impact of the working conditions is something that, to me, really affects the perceived value of my clothes.

Unfortunately, most t-shirts are made in essentially legal sweatshops by adults and often children who are barely paid. And that sucks.

What also sucks is that most companies are not required to tell us exactly where and under what conditions our clothes are manufactured.

The way I usually try to solve this problem when buying clothes is by purchasing things that are made in the U.S. It's not impossible to run a sweatshop here, but it's a lot harder than in countries like China, Vietnam, or Bangladesh.

For me, the ideal best value t-shirt would be one made in the U.S. by a factory that has good working conditions, pays their employees well, and treats them like the keystone part of the business they are.

So that's what I was looking for when shopping for a t-shirt: good quality natural fabrics, a well-constructed collar and overall fit, and made in the good ol' U.S. of A.

And that t-shirt exists in many forms. Look up organic, combed cotton, made in the U.S. t-shirt, and you'll find tons of options, but the price for those shirts usually ranges between $45 and $85.

And although I'm fortunate enough to be in a position to pay that much for a t-shirt, it was confusing and kind of unbelievable to me that a basic, good quality, ethically made t-shirt must be prohibitively expensive for most people.

Which leads me to part two of my story:

Part II: Why are good quality t-shirts so damn expensive?

Answering that question led me down a rabbit hole into the world of branded luxury apparel.

If you're like me, you probably think that the brands you buy clothes from manufacture their garments in factories they own and operate.

Well – while some do – most don't. Many of the most popular brands in the U.S. actually outsource the manufacturing of their clothes to specialized apparel factories. Nordstrom, for example, partners with 100+ manufacturers across the globe (but mostly in China) to create their clothes.

But these factories often don't work exclusively for one brand. That means the same manufacturer could be making clothes for Nordstrom, Old Navy, and Ralph Lauren all in the same day.

And when it comes to t-shirts, because it's a rather commodified garment, most brands just buy high-quality blank t-shirts from wholesale manufacturers, slap their logo and tag on it, and sell it back to you.

And after doing some sleuthing, I found out that these premium, luxury t-shirts that brands sell for ~$50, only cost around ~$10 from the manufacturer.

Now, before we get our pitchforks out and start complaining about corporate greed, there are a few legitimate reasons for that 5x markup.

- The first is that there is labor involved in managing and fulfilling orders, and those people have to get paid.

- The second is that when buying inventory in bulk, there's a thing called dead stock. That's inventory that you buy but don't sell, and the cost of every t-shirt you do sell needs to incorporate the expected cost of dead stock.

- Finally, there's the cost of marketing. Before a brand can sell you a shirt, you need to know about that shirt. Which mostly means they need to buy ads. This is called the "customer acquisition cost" and is usually the largest expense for apparel brands.

Knowing all this I can see why these premium t-shirts are often so expensive. However, it also does prove that the reason their expensive is not because they are inherently expensive to produce; they're expensive simply because the companies that resell them have profit margins they want to hit and costs associated with hitting those margins.

Which led me to a question that sparks part three of my story:

Part III: Why don't we just buy these shirts directly from the suppliers?

Well, unfortunately most of these factories don't sell to consumers like you and me. They're wholesalers. They only sell to companies.

To buy from them, you need to register a business, apply for a seller's permit and a tax ID, apply and get approved for a wholesale license with the manufacturer, talk to one of their sales reps to put in an order – which are all things that most people are not going to do to buy a couple t-shirts.

...

But I'm not most people.

...

Hi. My name's Drew Lyton, and I'm the proud proprietor and wholesale buyer for Chickadee Apparel, LLC.

I ended up buying shirts from a few companies, but the two I liked the most were U.S. Standard Apparel (USSA) and Behind The Scenes Apparel (BTSA).

USSA is one of the only vertically integrated garment manufacturers in the U.S. That means they spin, weave, knit, cut, sew, and dye all of their garments in their 50% solar-powered factory in Vernon, California. They pay their people well and have a public factory tour that you can watch on YouTube.

And their shirts are great. I bought a few of their combed cotton daily tees, which feel and look great and only cost me $8 a shirt.

BTSA is a minority owned garment manufacturer in Compton, California. They focus a ton on providing extremely good benefits and working conditions for their employees. I'd say their shirts feel even better than US Standard Apparel's, but they're almost twice as expensive at ~$14 a shirt.

But again, to put this in perspective, that's nearly 4x less expensive than what this shirt would cost retail and 100x better than the shirts you can buy retail at that price point.

Which means, between USSA and BTSA, I think I've found the best value t-shirts made in the USA 🇺🇸🎉.

Now, for most people that's where this story would end. I got my t-shirts, saved a few bucks, and had a great story to tell. But, again, I'm not most people.

And I started asking myself:

What if I let you buy these t-shirts

What if I started an apparel company that didn't spend any money on marketing, didn't acquire any dead stock, and we did like four bulk orders a year, operating as a simple bridge between manufacturers and you—selling the items essentially at cost?

We could support some great local garment manufacturers, help people see the value in owning higher quality clothing, and do it all at an affordable price.

If you're interested in this idea and potentially being part of our first order, fill out this form!